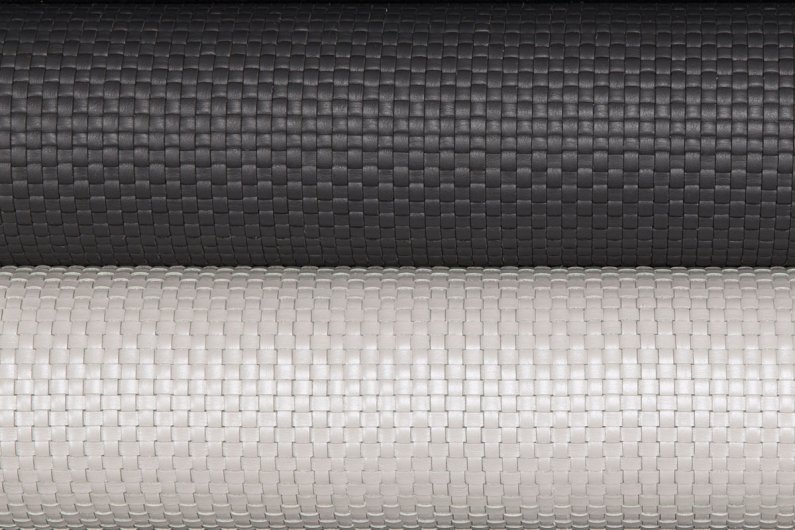

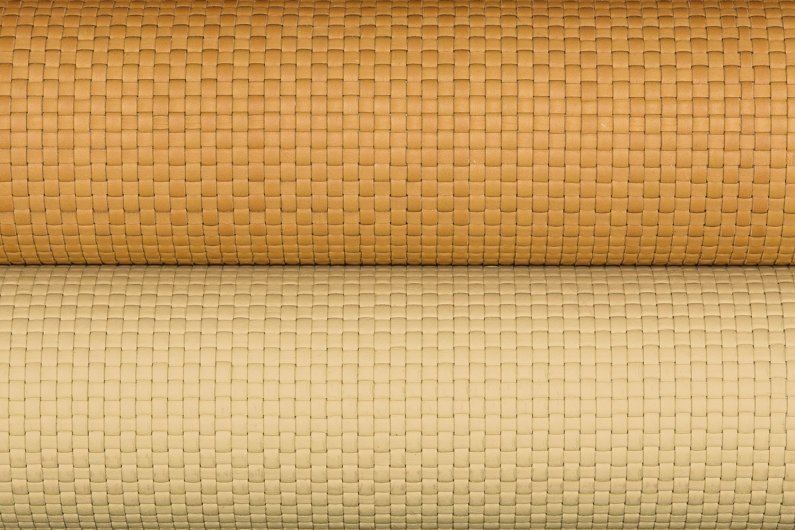

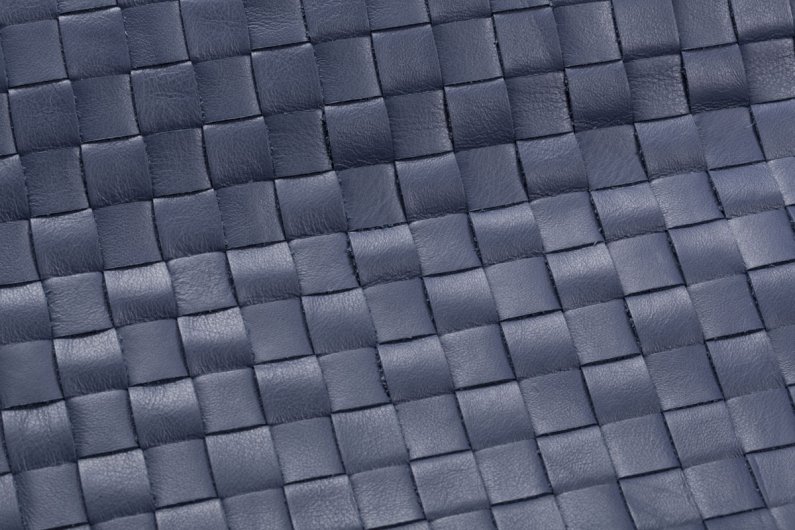

Color Guide

Leather Weave (LW)

Leather Weave takes quality upholstery leather and creates depth and pattern by weaving thin strips together. This unique covering for upholstery and architectural products offers a distinct look with a more efficient use of leather as an entire hide can be used to make the product. Any Spinneybeck leather may be used to create custom Leather Weave including pearlized, sueded, and four patent leathers. Up to three different leathers styles may be used to create subtle or dramatic patterning. Also choose from 0.2 in (5 mm) or 0.28 in (7 mm) strip width and roll width of 27 in (69 cm), 36 in (91 cm), or 38 in (97 cm).

- Content European cowhide

- Origin Italy

- Pattern Options One Leather, Two Leather, Three Leather

- Leather Types AD, AF, AL, AQ, AU, CA, CO, CV, DE, DT, DV, ES, ET, FE, HT, LC, LU, RA, RU, SA, SL, VO, VP, VZ

- Refer to Color Book for available colors

- Strip Width Options 0.2 in (5 mm) or 0.28 in (7 mm)

- Roll Width Options 27 in (69 cm), 36 in (91 cm), 38 in (97 cm)

- Maximum Length 80 lin ft (24.4 m)

- Thickness Varies by leather

- Weight Varies by leather

- Backing Cotton backing for stability

- Minimum 55 sq ft (5.1 sq m) and an overrun of up to 10 percent is required to guarantee no shortage of material

- Primary Uses Upholstery, wall panels

- Industry Automotive, aviation, contract, hospitality, marine, residential

- Maintenance For finished leathers, wipe with a cool, damp cloth. For tougher soiling, use a pH balanced soap such as Dawn at a 1:10 ratio of soap to water, then rinse. Repeat if needed. For naked (aniline) leathers, wipe the entire surface with a soft cloth and cool water to even out any abrasions or stains. Do not spot rub, as this will darken only the treated area. Occasional use of leather cleaner and protector is recommended for all leather types. Other leather cleaners, such as saddle soap or household cleaners that may contain harsh chemicals, alcohol, or ink removers, should never be used.

- Lead Time Made to order and 6–8 week lead time will apply

Swatches displayed are intended to represent the product color. Variations may occur due to individual monitor settings. For the most accurate representation, we recommend requesting a physical sample prior to final selection.