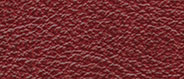

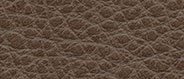

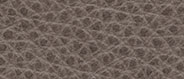

Color Guide

Hand Tipped (HT)

This two-toned leather is clearly in a class by itself. Hand Tipped is crafted from a premium selection of full grain raw material and the pebble grain character is the result of a specific retannage and extended milling process. The premium, select raw material required to produce Hand Tipped originates from northern Italy, southern Germany, and Switzerland. The two-tone effect is achieved through the base dye coloration and treatment where the tip of the pebble grain is dyed with a dark overtone applied by hand. The surface of the leather is further enhanced with a light clear coat application followed with a specialized ironing process.

- Content European cowhide

- Origin Italy

- Hide Size 60–65 sq ft (5.6–6.0 sq m)

- Thickness 1.4–1.6 mm

- Weight 3.5–4.0 oz / sq ft (1068–1221 g / sq m)

- Grain Full

- Grain Texture Pronounced pebble

- Tannage Chrome

- Dye Aniline

- Finish Light

- Primary Uses Upholstery, handrails, rugs, wall panels, architectural applications

- Industry Automotive, aviation, contract, hospitality, marine, residential

- Maintenance Wipe with a cool, damp cloth. For tougher soiling, use a pH-balanced soap and rinse. Repeat, if needed. Occasional use of Spinneybeck Finished Leather Cleaner, Conditioner & Protector is recommended. Other leather cleaners such as saddle soap or household cleaners that may contain harsh chemicals, alcohol or ink removers should never be used.

- Custom Custom colors not available

- Special Services Flame treatment, perforated, and embossed available with an upcharge

- Colorfastness to Light Class 4

- Colorfastness to Crocking Class 4–5 (dry), Class 4 (wet)

- Flammability ASTM E 84: Class A (flame treated)

- Boston Fire Dept BFD IX-1: Pass (flame treated)

- BS EN1021 (Part I and Part II): Pass

- BS 5852 Crib 5 and Crib 7: Pass (flame treated)

- CAL 117: Pass

- CAL 133: Successfully used in CAL 133 applications with Firegard F187 fire backer material or equivalent (flame treated)

- Cigarette Ignition Resistance NFPA 260: Class 1

- FAR 25.853(a) 60 sec vertical burn, 12 sec vertical burn. Oil burner-fire block: Pass

- IMO Resolution A.652(16): Pass

- IMO Resolution A.653(16) Part 2 and 5: Pass (flame treated)

- NF P 95 512 1986 (Electric Burner Test): Class M1 (flame treated)

- Durability + Strength Abrasion ASTM D 7255: n/a

- Breaking Force ASTM D 2208: 260 lb

- Elongation ASTM D 2211: 30–50% at 50 lb

- Flex ASTM D 2097: 70,000 flexes

- Tearing Strength ASTM D 4705: 40 lb