Color Guide

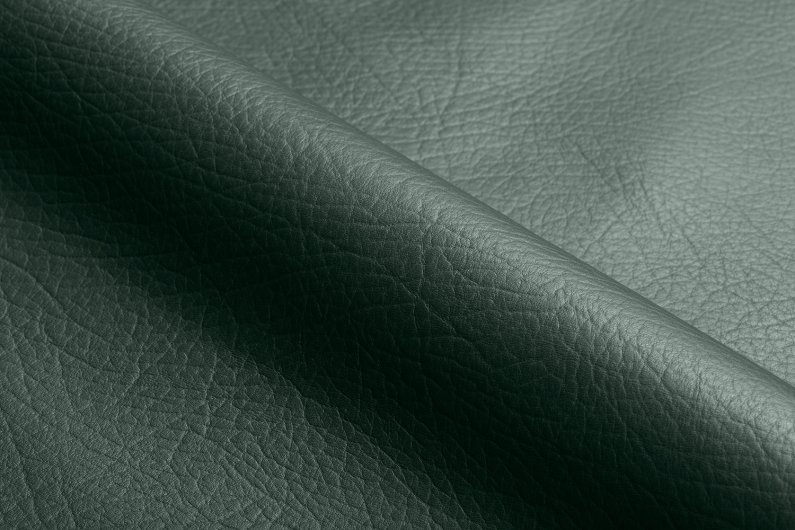

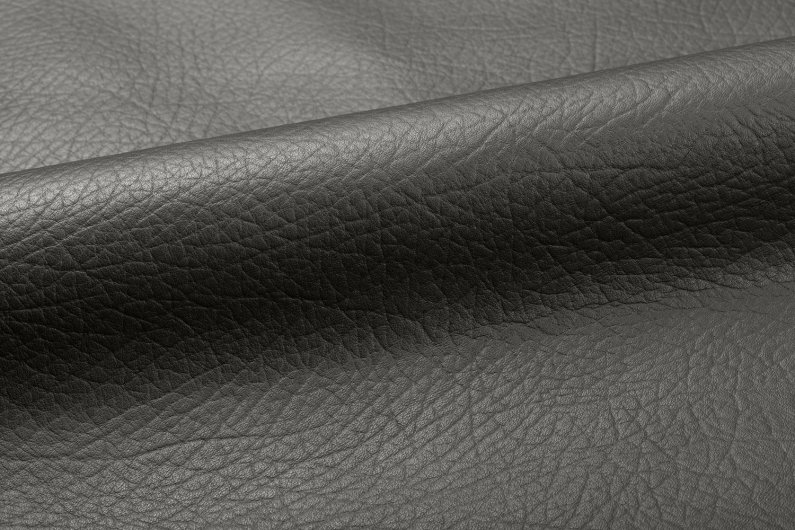

Ducale (DL)

Ducale is a select, embossed and shrunken full grain upholstery leather. The special combination vegetable retannage provides the leather with the additional body and fiber tightness required to hold firm the shrunken grain texture of this unique leather. The high quality dyes allow a greater saturation and dye enrichment than ordinary upholstery leathers. Ducale features a breathable protective finish which is impregnated into the leather, becoming an integral part of the material, and protects the surface while keeping the user cool.

- Content European cowhide

- Origin Italy

- Hide Size 50–55 sq ft (4.6–5.1 sq m)

- Thickness 1.3–1.5 mm

- Weight 3.25–3.75 oz / sq ft (992–1144 g / sq m)

- Grain Full

- Grain Texture Embossed shrunken

- Tannage Chrome

- Dye Aniline

- Finish Medium

- Primary Uses Upholstery, handrails, wall panels, architectural applications

- Industry Automotive, aviation, contract, hospitality, marine, residential

- Maintenance Wipe with a cool, damp cloth. For tougher soiling, use a pH-balanced soap and rinse. Repeat, if needed. Occasional use of Spinneybeck Finished Leather Cleaner, Conditioner & Protector or Finished Leather Maintenance Kit is recommended. Other leather cleaners such as saddle soap or household cleaners that may contain harsh chemicals, alcohol or ink removers should never be used.

- Custom Custom colors available

- Special Services Flame treatment, perforated, and embossed available with an upcharge

- Colorfastness to Light Class 4

- Colorfastness to Crocking Class 4–5 (dry), Class 4 (wet)

- Flammability ASTM E 84: Class A (flame treated)

- Boston Fire Dept BFD IX-1: Pass (flame treated)

- BS EN1021 (Part I and Part II): Pass

- BS 5852 Crib 5 and Crib 7: Pass (flame treated)

- CAL 117: Pass

- CAL 133: Successfully used in CAL 133 applications with Firegard F187 fire backer material or equivalent (flame treated)

- Cigarette Ignition Resistance NFPA 260: Class 1

- FAR 25.853(a) 60 sec vertical burn, 12 sec vertical burn. Oil burner-fire block: Pass

- IMO Resolution A.652(16): Pass

- IMO Resolution A.653(16) Part 2 and 5: Pass (flame treated)

- NF P 95 512 1986 (Electric Burner Test): Class M1 (flame treated)

- Durability + Strength Abrasion ASTM D 7255: n/a

- Breaking Force ASTM D 2208: 150 lb

- Elongation ASTM D 2211: 30–50% at 50 lb

- Flex ASTM D 2097: 70,000 flexes

- Tearing Strength ASTM D 4705: 25 lb